固体环氧树脂

| 订货号: | MM-80574-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

|

|

|

Product Description

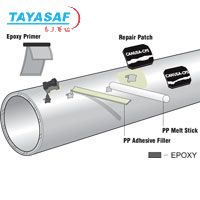

CANUSA-CPS E Primer is a specially formulated 100% volume solids (solventless) two-component epoxy. Recommended use is as a primer in a three-layer coating system for superior corrosion protection of field welded joints of steel pipes.

Using Canusa's proven method of force curing the E Primer to the steel enables the installer to "pre-inspect" the joint prior to sleeve application. This provides the assurance that the pipe is fully protected and it will not be displaced and exposed to corrosive contaminants during the aligning and shrinking stages of sleeve installation.

Available in bulk quantity or bubble pack option, E Primer kits are provided with a pair of latex gloves and an application pad.,

|

Specifications

|

Property |

CANUSA E Primer |

|

Color |

Black |

|

Volume Solids |

100% |

|

Weight Solids |

100% |

|

Mixing Ratio |

(by volume) - 4 parts of base to 1 part of cure (by weight) - 6.1 parts of base to 1 part of cure |

|

Typical Coverage |

20 sq.m./US gallon (215 sq.ft/US gallon) or 5.3 sq.m/liter ( 57 sq.ft/liter). This coverage is based on 6 mils of thickness & assuming 20% waste factor |

|

Specific Gravity |

E Primer Base - 1.58 ± 0.03 (ASTM D 1475) E Primer Cure - 1.04 ± 0.02 (ASTM D 1475) |

|

Viscosity |

E Primer Base - 14,000 ± 2,000 cps at 60°C, # 7 Spindle at 10rpm E Primer Cure - 30 ± 3 seconds (ASTM D1200 # 4 Ford cup @ 25°C) |

|

Typical Thickness |

4 to 6 mils (0.10 to 0.15 mm) |

|

Number of Coats |

One |

|

Pot Life |

20 minutes @ 23°C (73°F) |

|

Shelf Life |

3 years @ 23°C, out of direct sunlight. Shelf life will be lesser at higher temperatures. |

|

Flash Point |

E Primer Base - 93°C (200°F) E Primer Cure - 92°C (198°F) |

|

Thinner |

Do not dilute. |

|

Minimum Curing Temperature |

10°C (50°F) |

|

Safety |

Handle with care. Before and during use, observe all safety labels on packaging and paint containers, consult CANUSA Material Safety Data Sheets and follow all local or national safety regulations. Harmful or fatal if swallowed; immediately seek medical assistance if swallowed. Avoid inhalation if possible solvent vapors or paint mist, as well as paint contact with skin and eyes. Apply only in well ventilated areas and ensure that adequate forced ventilation exists when applying paint in confined spaces or when the air is stagnant. Always take precautions against risks of fire and explosion. |

Application

Prepare the pipe surface as recommended in the product-specific Installation Guide.

Follow the mixing instructions that are contained within the epoxy packaging.

With a gloved hand, pour the combined mixture onto the pipe.

Begin spreading the epoxy primer (to a uniform thickness) circumferentially around the pipe surface using the applicator pad.

Use a wet film thickness gauge to ensure a correct, uniform thickness has been achieve all around the pipe.

Amount Required

Epoxy required for 300 mm / 12" cutback. For other cutbacks, divide by 12 and multiply by new cutback in inches.

Example: 200 mm (8") cutback on 610 mm diameter pipe

Base: 88 mL x 8/12 = 60 mL base

Cure: 22 mL x 8/12 = 15 mL cure

Example: 200 mm (8") cutback on 610 mm diameter pipe

Base: 88 mL x 8/12 = 60 mL base

Cure: 22 mL x 8/12 = 15 mL cure

, Mixing ratio by volume of base to cure is 4 : 1. Therefore, for 1 US gallon of Base, 0.25 US gallons of cure will be required.

Due to pot life limitations, it may be impractical to coat multiple joints with the same epoxy kit.

Due to pot life limitations, it may be impractical to coat multiple joints with the same epoxy kit.

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

AQW-FF热缩套管订货号:MM-08451-00

AQW-FF热缩套管订货号:MM-08451-00 热缩管保护产品订货号:MM-08446-00

热缩管保护产品订货号:MM-08446-00 热收缩膜订货号:MM-80568-00

热收缩膜订货号:MM-80568-00

热收缩套/热收缩带订货号:MM-80569-00 热收缩水管道腐蚀防护套订货号:MM-80570-00

热收缩水管道腐蚀防护套订货号:MM-80570-00 套管扣合式套筒订货号:MM-80571-00

套管扣合式套筒订货号:MM-80571-00 GTS-65传输管道保护套订货号:MM-80572-00

GTS-65传输管道保护套订货号:MM-80572-00 CANUSA定向钻井工具包订货号:MM-75494-00

CANUSA定向钻井工具包订货号:MM-75494-00 CRP的管道维修产品订货号:MM-80573-00

CRP的管道维修产品订货号:MM-80573-00 环绕式管道套订货号:MM-80575-00

环绕式管道套订货号:MM-80575-00 AQW-FPK保护套件订货号:MM-80577-00

AQW-FPK保护套件订货号:MM-80577-00 CANUSA高收缩套订货号:MM-80576-00

CANUSA高收缩套订货号:MM-80576-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-80574-00 | 固体环氧树脂 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

您最近浏览的商品

美国MI

美国MI