PSI能源应用套管隔离垫片

| 订货号: | MM-80646-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

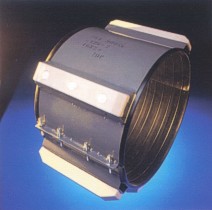

Coated Steel

PSI polyvinyl chloride coated (PVC) steel casing isolators are often selected due to their strength and excellent corrosion resistance.

Model C12G-2: Coated Steel casing isolator with a 12" (305 mm) wide steel band and 2" (50.8 mm) wide glass reinforced runners.

|

Stainless Steel

Typical spacing for all PSI metallic casing isolators / spacers

A8 / C8 / S8 = 7' (2.1 m) to 10' (3.0 m)

A12 / C12 / S12 = 8' (2.4 m) to 12' (3.7 m)

An isolator/spacer should be placed within 2' (0.6 m) on each side of a coupling or joint and within 1' (0.3 m) of each end of the casing. |

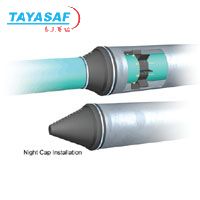

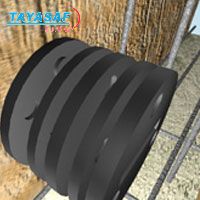

Ranger Il®, All Non-metallic

|

An all non-metallic spacer system designed to ease carrier pipe insertion, reduce inventory costs, make installation quick and easy to last for the life of the piping system.

Features:

All non-metallic. No nuts, bolts, washers or any other metal parts to corrode or degrade over time.

Segmented pieces - small inventory may be used to accommodate a large variety of pipe styles, types and diameters. No extra trips from job site to warehouse for additional parts.

Easy assembly. Simply slide the segments together and ratchet tight with the patented Slide-Lock connecting system.

Wide variety of runner heights to allow numerous options for pipe positioning within the casing. |

|

Manufactured from UV resistant polypropylene.

No special tools required for installation.

Accommodates plastic, ductile iron and steel carrier pipe (not suitable for concrete pipe).

Model Options:

For carrier pipe diameters from 0.83" (21 mm) to 37.60" (955 mm) in diameter. See our Ranger II web page for runner heights, configuration options, ordering information and installation instructions.

For carrier pipe diameters from 0.83" (21 mm) to 37.60" (955 mm) in diameter. See our Ranger II web page for runner heights, configuration options, ordering information and installation instructions.

Band/Runner Segment Specifications

Material, UV resistant polypropylene.

Compressive Strength, 3,000 lbs/sq.in (211 kg/sq.m)

Temperature, -40ºF to +180ºF (-40ºC to +82ºC)

Impact Strength, 1.5 ft.lb/sq.in (10.34 kPa)

Dielectric Strength, 800 Volts/mil min.

Color, Black

Liner, None

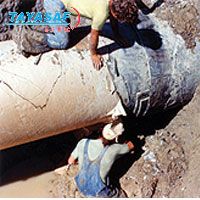

Typical Installation

Based on 20' (6.1 m) carrier pipe segments in a casing of not more than 300' (91.5 m). Consult CCP for longer casings and for concrete pipe.

Based on 20' (6.1 m) carrier pipe segments in a casing of not more than 300' (91.5 m). Consult CCP for longer casings and for concrete pipe.

Typical Specification

Casing spacers shall be all non-metallic (polypropylene), molded in segments for field assembly without any special tools. Spacer segments shall be secured around carrier pipe by insertion of a cinching spline. The casing spacer polymer shall contain ultraviolet inhibitors and shall have a minimum compressive strength of 3,000 psi, an 800 Volts/mil dielectric strength and impact strength of 1.5 ft-Ibs/inch. Each casing spacer shall have full length, integrally molded skids extending beyond the bell or mechanical joint of the carrier pipe.

Each casing spacer shall be manufactured at a facility that has a Registered ISO 9001:2000 Quality Management System. Copy of current ISO 9001:2000 Registration shall be provided with material submittal.

Approved vendor: Corrosion Control Products Company.

Recommended Maximum Spacing

All Ranger II® Isolators/Spacers should not exceed 8' (2.4 m) center to center.

An isolator/spacer should be placed within 2' (0.6 m) on each side of a coupling or joint and within 1' (0.3 m) of each end of the casing. For more details on spacing, contact CCP.

An isolator/spacer should be placed within 2' (0.6 m) on each side of a coupling or joint and within 1' (0.3 m) of each end of the casing. For more details on spacing, contact CCP.

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

密封胶订货号:MM-80641-00

密封胶订货号:MM-80641-00 非金属垫片套管订货号:MM-80642-00

非金属垫片套管订货号:MM-80642-00 PSI管道密封和绝缘体订货号:MM-80643-00

PSI管道密封和绝缘体订货号:MM-80643-00 PSI第二套管垫片订货号:MM-80644-00

PSI第二套管垫片订货号:MM-80644-00 PSI-C金属外壳垫片订货号:MM-80645-00

PSI-C金属外壳垫片订货号:MM-80645-00 PSI-R密封件订货号:MM-80647-00

PSI-R密封件订货号:MM-80647-00 PSI-W缠绕套管端密封件订货号:MM-80648-00

PSI-W缠绕套管端密封件订货号:MM-80648-00 绝缘套管订货号:MM-80649-00

绝缘套管订货号:MM-80649-00 密封包装袋订货号:MM-67884-00

密封包装袋订货号:MM-67884-00 PSI连接密封®模块化密封订货号:MM-80650-00

PSI连接密封®模块化密封订货号:MM-80650-00 世纪线管渗透套订货号:MM-80651-00

世纪线管渗透套订货号:MM-80651-00 PSI的细胞铸磁盘订货号:MM-80652-00

PSI的细胞铸磁盘订货号:MM-80652-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-80646-00 | PSI能源应用套管隔离垫片 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

您最近浏览的商品

美国MI

美国MI