Pikotek-IsoCore™垫片

| 订货号: | MM-80676-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

Pikotek is a name synonymous with quality and high reliability when it comes to electrical flange isolation gaskets. Pikotek gaskets and insulating kits are designed to operate in the most demanding applications found throughout the world without the worry of breaking, leaking or shorting. In addition to its line of high pressure, very critical service insulating gaskets (VCS), Pikotek created the IsoCore™, a highly reliable, cost-effective alternative to conventional insulating gaskets and kits for non-critical, low pressure applications.

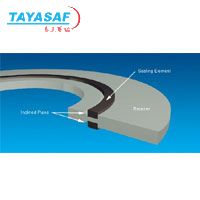

The IsoCore insulating gasket is manufactured from Neoprene coated glass-reinforced epoxy (NEMA grade G- 10) in place of the failure-prone conventional phenolic reinforcing material. Glass-reinforced epoxy ("GRE") is many times stronger than conventional paper grade or fabric-reinforced phenolic. The result is that the IsoCore is an economical, low pressure insulating gasket that is much stronger in compression, much more resistant to stress fractures and breakage, and thus much more reliable than conventional phenolic insulating gaskets.

In addition to being much stronger, the IsoCore gasket has a significantly lower fluid/gas absorption factor and higher dielectric strength than phenolic materials (see table). This provides increased electrical insulation with less fluid migration through the central gasket material, which can ultimately result in shorting and loss of tensile strength. Finally, the IsoCore gasket uses a thicker layer of facing Neoprene (1/16") than do conventional coated insulating gaskets. This results in lower initial seating stress, more sealing forgiveness, and more resistance to leaks caused by pressure cycling, thermal cycling and/or vibration.

Advantages & Benefits

High-reliability sealing at low pressure (up to 750 psig).

Superior electrical isolation.

Cost-effective alternative to phenolic or inferior non-reinforced sheet gasket materials.

GRE washers made of the same high compressive strength material for added reliability.

No phenolic or polypropylene material used.

1/8" (.125" or 3.2 mm) cross section with 1/16" GRE core.

1/32" (.031" or 0.8 mm) thick neoprene facing material.

High compressive strength gasket core results in less breakage and increased reliability.

Thicker facing material provides enhanced sealing on older flanges.

Full-length sleeves are designed to fit inside of washers and seal out moisture.

GRE washers made of high compressive strength material for added reliability.

Mylar sleeves standard with GRE available for even greater reliability against mishandling.

Double washer sets provide added assurance for electrical insulation.

Metal washers are either high-strength, zinc-plated carbon steel or stainless steel.

Manufactured to complement the field-proven Pikotek line of flange isolation kits.

Available in full face (Type E) or raised face (Type F).

Meets all low-pressure flange specifications (i.e., ANSI, AWWA, DIN, etc.)

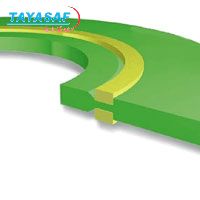

IsoCore™ Design

Why The IsoCore Is Superior to Conventional Insulating Gaskets

Pikotek products are well known for their high reliability, superior sealing characteristics and outstanding electrical insulation properties. Pikotek created this reputation by supplying only superior materials in engineered products. However, for those cases where economics prohibit specifying engineered products, especially in non-critical service applications (e.g. low pressure and/or non-aggressive media), Pikotek created the IsoCore, a cost effective insulating gasket made with superior grade materials. The IsoCore bridges the gap between Pikotek's sophisticated VCS/PGE gaskets and conventional neoprene-coated phenolic or cut-sheet gaskets with phenolic washers and polypropylene sleeves. The IsoCore was designed to provide operational reliability in an economical, cost effective package.

As with Pikotek's other products, the IsoCore uses only materials that will perform reliably over a wide range of conditions. The GRE center of the IsoCore is far stronger and much more resilient than traditional materials. Pikotek only uses GRE insulating washers and either Mylar or GRE sleeves, which have a far greater reliability than conventional materials. Inferior materials such as phenolic, Minlon or polypropylene are subject to crushing, cracking, breaking and thread pinch, which compromise product integrity, create leaks and result in electrical shorting. The IsoCore eliminates these problems in an affordable package.

Insulating Sleeve Options

IsoCore insulating kits come standard with cost-effective Mylar sleeves for insulating the stud bolts. Mylar is superior to either phenolic or polypropylene, which is the standard material in most conventional insulating kits. If requested, GRE (Glass-Reinforced Epoxy) sleeves can be supplied and are the best solution for all around reliability. These sleeves are extremely strong and can withstand significantly more abuse and harsh conditions than any other sleeve material available. Both Mylar and GRE offer excellent resistance to crushing, cracking, breaking and thread pinch compared to other sleeve materials.

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

绝缘法兰订货号:MM-80658-00

绝缘法兰订货号:MM-80658-00 新型绝缘法兰订货号:MM-80659-00

新型绝缘法兰订货号:MM-80659-00 PSI绝缘法兰订货号:MM-80667-00

PSI绝缘法兰订货号:MM-80667-00 PSI后卫密封垫片订货号:MM-80667-00

PSI后卫密封垫片订货号:MM-80667-00 PSI250及251密封垫片订货号:MM-80668-00

PSI250及251密封垫片订货号:MM-80668-00 PSI隔离密封垫片订货号:MM-80662-00

PSI隔离密封垫片订货号:MM-80662-00 PSI-GasketSeal密封垫片订货号:MM-80670-00

PSI-GasketSeal密封垫片订货号:MM-80670-00 PSI-FlangeMate密封垫片订货号:MM-80670-00

PSI-FlangeMate密封垫片订货号:MM-80670-00 PSI传统密封垫片订货号:MM-80671-00

PSI传统密封垫片订货号:MM-80671-00 PSI的法兰分离试剂盒订货号:MM-49639-00

PSI的法兰分离试剂盒订货号:MM-49639-00 PSI隔离套和垫圈订货号:MM-80664-00

PSI隔离套和垫圈订货号:MM-80664-00 PSI-LineSeal临界密封用垫片订货号:MM-80666-00

PSI-LineSeal临界密封用垫片订货号:MM-80666-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-80676-00 | Pikotek-IsoCore™垫片 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

您最近浏览的商品

美国MI

美国MI