|

Housing: |

Stainless steel with 40 mm insulation, (material 1.4301/ SS304) / PS / PC (GF10) Option: material 1.4571/ SS316Ti; SS304 EPOXY-coated; SS316Ti EPOXY-coated |

|

Thermostatic control: |

Self-contained cooling / heating with 4 settings, no-frost. Temperature in sample compartment: 4°C (adjustable from 0,0-9,9°C) |

|

Control: |

Microprocessor control, foil keyboard, back lit four-line LC-display |

|

Data logger: |

Nonvolatile data memory; storage of sampling and malfunction data like sample extractions, bottle changes, messages, external signals |

|

Programming: |

6 user programs (can be edited freely) |

|

Program start options: |

Immediately; at a certain time; by an external signal |

|

Program stop options: |

End of sampling program after one program run; continuous operation |

|

Pause mode: |

Interruption of program run at any time |

|

Overfilling protection: |

Adjustable from 1–999 samples/bottle |

|

Interval setting: |

1 min. to 99 h 59 min. in steps of 1 minute |

|

Pulse setting: |

1 to 255 pulses/sample |

|

Manual sample extraction: |

Possible at any time without interrupting the current program run |

|

Program protection: |

Up to 5 years after voltage loss |

|

Interface: |

RS 232 |

|

Communication: |

Modbus, connection via DP PROFIBUS optional |

|

Modem GSM communication: |

Optional (in combination with PC software) |

|

Languages: |

Multi-language, selectable |

|

Signal inputs: |

• 1 x analogue: 4-20 mA, optional 0-20 mA, minimum voltage 3,3 V (optocoupler) • 5 x digital (flow, event, 3 inputs can be programmed freely) |

|

Signal outputs status messages: |

Max. 8 digital outputs, depending on device version; 5 or 6 outputs freely programmable |

|

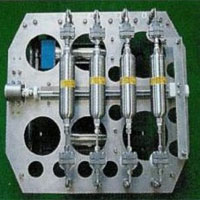

Sampling method: |

-Vacuum system 20-350 ml -Vacuum system 20-500 ml optional -Vacuum flow-proportional system 20-350 ml optional -Bypass system 20-250 ml optional |

|

Single sample volume accuracy: |

< 2,8 % |

|

Suction height: |

max. 8 m (at 1013hPa and stagnant medium) |

|

Pumping speed: |

>0,5 m/s at suction height up to at least 7,8 m (at 1013h Pa); pump capacity can be adjusted electronically |

|

Suction hose: |

PVC, L=7,5 m, ID=12 mm (ID 16 mm at flow-proportional option). Max. hose length 30 m |

|

Sampling modes: |

Time-related, flow-dependent, flow-proportional, event-related, manual sample extraction |

|

Bottle variants: |

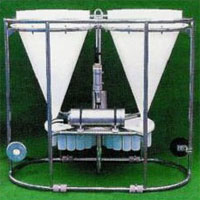

2 x 10 l PE 4 x 5 l PE 12 x 1,6 l glass Duran50 optional: 24 x 2 l glass Duran50 (1400 x 800 x 850 mm) |

|

Overall dimensions: |

(Hxwxd) 2 x 10 l , 4 x 5 l, 12 x 1,6 l: 1290 (1930*) x 690 x 645 mm or 24 x 2 l: 1400 (2175*) x 800 x 850 mm *) with opened top |

|

Weight: |

115 kg with bottle option 2 x 10 L PE; higher weight with other bottle and/or glass bottle options |

|

Power supply: |

230 V / 115 V /AC |

|

Power requirement number of samples: |

Approx. 350VA (with cooling) |

|

Ambient temperature: |

-20 – 40°C |

|

Sample temperature: |

0 – 40°C |

|

Standards: |

Device meets ISO 5667 standard |

|

Wetted materials: |

PVC, Silicone, PS, PE, EPDM (optional: metering vessel Duran50, sinker weight SS304) |

|

Accessoires: |

Plinth

Extraction unit, fixed or pendulous

Mobile version

Strainer basket

PC communication software

Status messages

Interior lighting

Main switch |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比