Nu-Bolt™

Designed by corrosion engineers, Nu-Bolt™ is a standard pipe U-Bolt modified with a variety of corrosion resistant treatments to provide reliable, long-term service in severe operating environments associated with offshore oil & gas production and coastal process facilities.

Type 316 alloy stainless steel is used as the structural metal. This is a molybdenum-bearing grade steel which gives the better overall corrosion resistance properties than Type 304 and higher creep strength at elevated temperatures. Type 316 resists chloride attack, and is ideal for use in marine atmospheres and other corrosive environments.

Polyshrink is applied over the shank of the U-Bolt to protect the paint system during installation. Polyshrink is not designed to protect the U-Bolt. The material is a crosslinked, high compressive strength, UV-stable polyolefin, and is good for continuous operation up to 230°F (110°C).

Standard, stocked U-Bolt coatings:

Hot Dip Galvanize – suitable for moderately aggressive areas.

SermaGard® – an aluminum-ceramic coating offering superior corrosion resistance in aggressive environments.

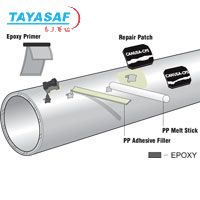

I-Rod®

I-Rod® is a high-strength thermoplastic rod in a half round configuration. I-Rod is inserted so the round surface interfaces with the pipe.

The half round profile:

Minimizes contact crevice, and thus eliminates moisture retention.

Provides a standoff between the pipe and support, and thus:

- Insulates electrically.

- Improves maintainability.

- Improves inspectability.

The high-strength thermoplastic material also:

Provides excellent compressive strength.

Is UV stable.

Has a low friction coefficient, which assists in pipe fitting when used as a beam dressing, and reduces coating damage during new construction.

When used independently as a beam dressing, I-Rod® is typically supplied in 5’ and 10’ lengths.

Specifications

I-Rod Specifications (Standard High Impact Thermoplastic)

|

Property Value |

Units |

ASTM Test |

Value |

|

Density, 73ºF |

- |

D792 |

1.41 |

|

Tensile Strength, 73ºF |

psi |

D638 |

9,800 |

|

Tensile Modulus of Elasticity, 73ºF |

psi |

D638 |

440,000 |

|

Elongation (at break), 73ºF |

% |

D638 |

30-60 |

|

Flexural Modulus of Elasticity, 73ºF |

psi |

D790 |

455,000 |

|

Flexural Strength, 73ºF |

psi |

D790 |

13,800 |

|

Compressive Strength, 10% def, 73ºF |

psi |

D695 |

16,000 |

|

Coefficient of Friction (dry vs steel) Dynamic |

- |

PTM 55007 |

0.25 |

|

IZOD Impact (notched), 73ºF |

ft-lbs/in of notch |

D256 |

1.5 |

|

Hardness, Rockwell, 73ºF |

- |

D785 |

119-122 |

|

Deformation Under Load |

% |

D621 |

1.0 |

|

Melting Point |

ºF |

D3418 |

329 |

|

Coefficient of Linear Expansion |

in/in/ºF |

E831 |

5.8 x 10-5 |

|

Continuous Service Temperature |

ºF |

- |

194 |

|

Heat Deflection Temperature, 264 psi |

ºF |

D648 |

220 |

|

Flammability Rating |

- |

VL94 |

HB |

|

Volume Resistivity |

Ohm-cm |

D257 |

1.0 x 1015 |

|

Dielectric Strength, Short Term |

V/mm |

D149 |

420 |

I-Rod HT Specifications (High-Temperature Applications)

|

Property Value |

Units |

ASTM Test |

Value |

|

Density, 73ºF |

- |

D792 |

1.28 |

|

Tensile Strength, 73ºF |

psi |

D638 |

16,500 |

|

Tensile Modulus of Elasticity, 73ºF |

psi |

D638 |

475,000 |

|

Elongation (at break), 73ºF |

% |

D638 |

80 |

|

Flexural Modulus of Elasticity, 73ºF |

psi |

D790 |

500,000 |

|

Flexural Strength, 73ºF |

psi |

D790 |

20,000 |

|

Compressive Modulus, 73ºF |

psi |

D695 |

480,000 |

|

Compressive Strength, 10% def, 73ºF |

psi |

D695 |

22,000 |

|

Coefficient of Friction (dry vs steel) Dynamic |

- |

PTM 55007 |

0.42 |

|

IZOD Impact (notched), 73ºF |

ft-lbs/in of notch |

D256 |

0.5 |

|

Hardness, 73ºF |

- |

D785 |

R125 / M112 |

|

Melting Point |

ºF |

D3418 |

N/A |

|

Coefficient of Linear Expansion |

in/in/ºF |

E831 |

3.1 x 10-5 |

|

Continuous Service Temperature |

ºF |

- |

340 |

|

Heat Deflection Temperature, 264 psi |

ºF |

D648 |

392 |

|

Flammability Rating |

- |

UL94 |

V-O |

|

Volume Resistivity |

Ohm-cm |

D257 |

6.7 x 1017 |

|

Dielectric Strength, Short Term |

V/mm |

D149 |

830 |

|

Thermal Conductivity |

BTU-in/ ft2 hr ºF |

C177 |

0.90 |

|

Flammability Rating |

|

UL94 |

V-O |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比